HDPE Pipe and Fusion Welding (High Density Polyethylene)

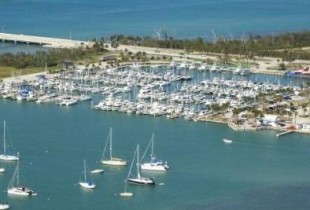

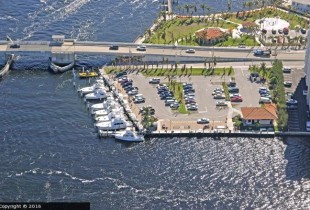

With a team of certified and highly trained welders, each having ample experience with complex projects, we are able to handle any marina dock designs and the most complicated underground utility applications. The Zager Global arsenal includes a variety of McElroy Fusion Welders for any size of HDPE pipe, so we are fully equipped to handle whatever your project specifications are. We invest heavily in training and stay up-to-date with the latest industry technologies by offering an array of HDPE classes for our team, as leaders in our field we are committed to staying prepared for every advance in our industry.

With a team of certified and highly trained welders, each having ample experience with complex projects, we are able to handle any marina dock designs and the most complicated underground utility applications. The Zager Global arsenal includes a variety of McElroy Fusion Welders for any size of HDPE pipe, so we are fully equipped to handle whatever your project specifications are. We invest heavily in training and stay up-to-date with the latest industry technologies by offering an array of HDPE classes for our team, as leaders in our field we are committed to staying prepared for every advance in our industry.

HDPE fusion welding is the process of bonding High Density Polyethylene piping together. By heating a section of each pipe beyond its melting point effectively changing its molecular structure. The pipe segments are held in place by a clamping mechanism and are set facing one another before heating.

Our master plumber Dale Zager has been licensed since 1984 and is a third-generation plumber.

He has meticulously trained and mentored our employees to maintain the exceptionally high standards that we hold for ourselves.

After having mixed the molecules of each pipe and the joint cools, the pipes will become one continuous length. The result is a new standardized pipe that will be equal in strength (if not stronger than) the segments alone. It takes a thorough understanding of this procedure and the equipment used to properly accomplish this process. From manipulating the heat source to the angle and even speed at which the pipes are joined, it’s critical to have properly trained personnel with the right equipment to ensure safety and quality. HDPE is one of the many commercial plumbing services we offer at Zager Global, Inc.

We offer and recommend HDPE Fusion Welding Systems over other systems due to the following advantages:

- Economical

- Corrosion Resistant

- Zero Leak-Rate

- Hydraulically Smooth

- Longevity

- Tappable

- Scratch Tolerant

- Readily Installed Small to Big Diameters

- Non-Toxic

- Lightweight, Flexible, and Coilable

- Listed and Approved

- Heat-Fused

- Mechanically Joined (as needed)

- Strong and Ductile

- Weather Resistant

- Freeze Resistant

- Abrasion Resistant

- Chemically Resistant

- Durable

- Inert

- Self Restrained Pipe (Monolithic)